i2i Launches Packaging Performance Programme

i2i europe, the Weedon Group’s creative design company, is launching a new packaging performance programme across the Group, to control and enhance both production and design performance.

To facilitate this move, the Group has moved its testing laboratory from its Manchester site to i2i’s base in Hednesford. The production side of the new performance programme involves testing the different boards manufactured within the Group to compile a matrix of data on materials and conversion processes. This will offer customers better information on suitable board qrades for their projects, helping to prevent over-specing, thereby saving customers’ money as well as natural resources, or under-specing, which could lead to packaging failing. The initiative will also support a move away from kraft papers (made from virgin fibre) to test liners, which are made from recycled paper.

At the same time, the information gathered will allow the Weedon Group to rationalise the range of boards it produces, which will improve speed to market and reduce waste from running unnecessary grades.

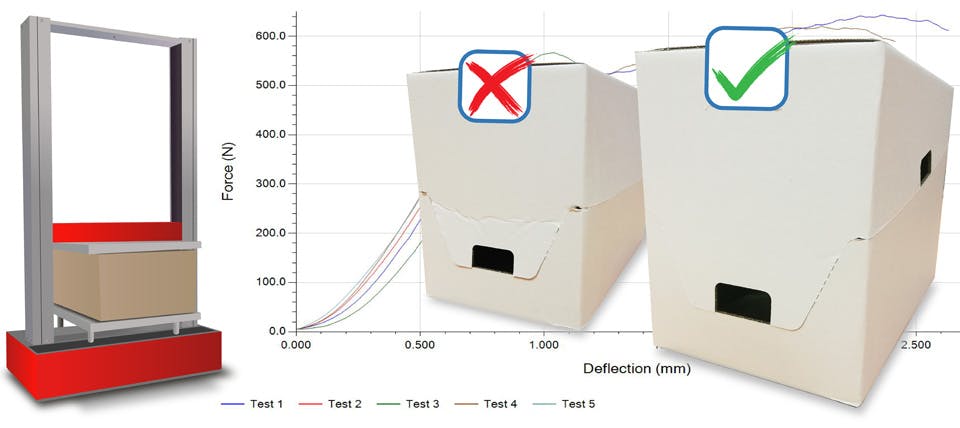

The Group’s structural designers regularly come up with innovative ideas to solve customers’ specific problems. For the design performance part of this programme, i2i europe will be able to test new ideas and designs and tell customers with scientific certainty – and in advance of mass production – whether their packaging is fit for purpose.

i2i europe is also offering independent testing services to anyone who needs analysis of packaging produced by other manufacturers.

The Weedon Group invested in new testing equipment early in 2020, and its testing laboratory is able to undertake edge testing of corrugated board, as well as to test its compression strength (how much load the board can withstand before it collapses), its weight and its burst strength (how much pressure it can tolerate before it fails).

The lab will continue to support production at both sites, enabling Weedon PSC in Hednesford and Weedon Corrugated Products in Manchester to check packaging performance and raw materials, and to test the sheet board manufactured on the Group’s in-house corrugator at Weedon Corrugated Products, to ensure it meets required standards and specifications

Edd Perry, Group Creative and Innovation Manager, comments:

“Adding value to our customers is one of our top priorities. The introduction of our packaging performance programme means that, if customers are specifying too high a board grade, we will be able to tell them that they can economise safely, while still providing good protection. This could save them a considerable amount of money. Anything that reduces the use of unnecessary raw materials and prevents waste is also better for our planet and in line with our Group sustainability goals.

“At the same time, we can provide peace of mind to our customers by testing our new designs for their packaging, and demonstrate that it will perform as required, before they commit to bulk production.

“In addition, i2i’s testing programme will improve the Group’s profitability, and reduce our environmental impact. We currently manufacture nearly 300 different board grades in-house. By the systematic analysis of the capabilities of these board grades, we hope to streamline our offering and reduce waste.”

For further information in relation to this news release, please contact:

John Weedon, Managing Director of the Weedon Group, on 01543 423838.

Weedon Group plant based packaging and displays